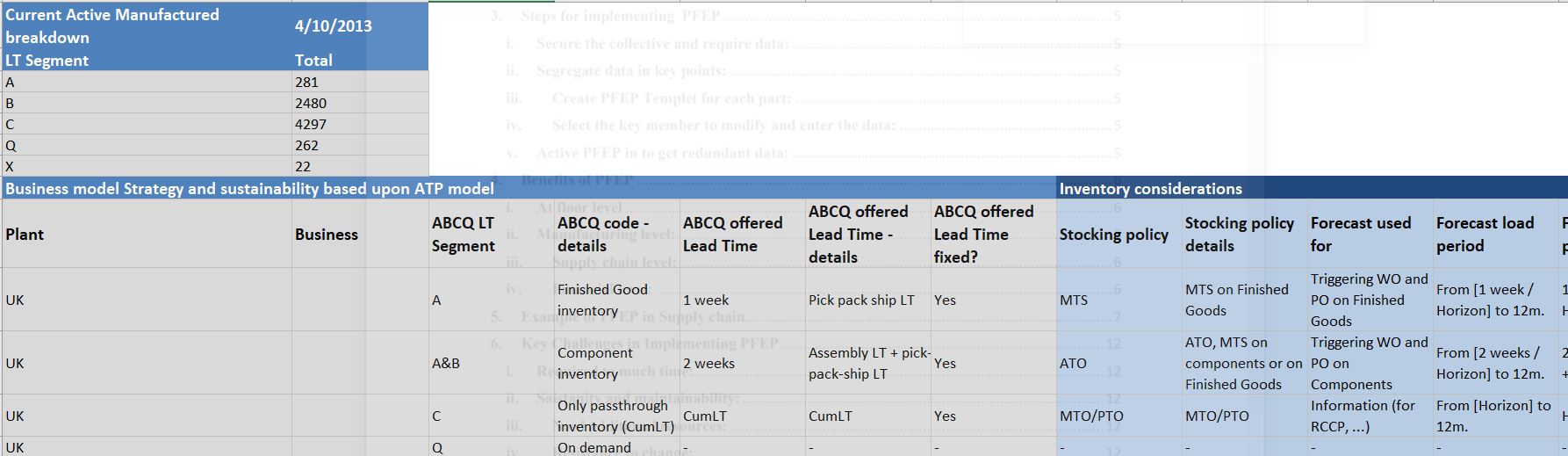

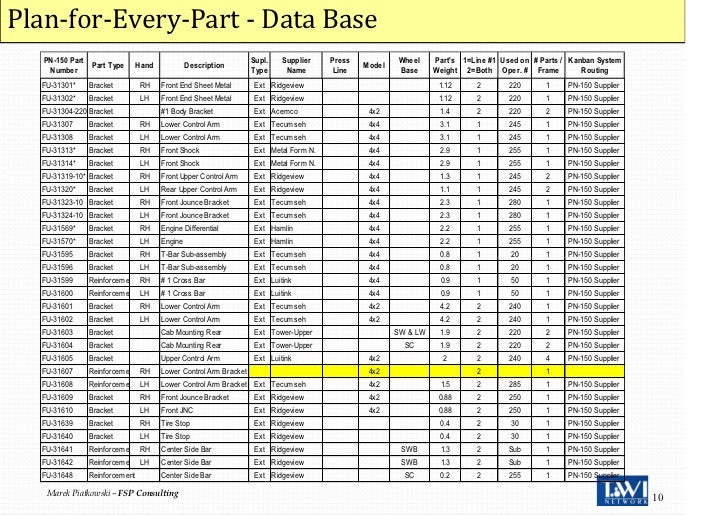

Plan For Every Part Template - In summary, the process to implement pfep should follow a stepped approach. Download a free pfep template and see example… Select the most efficient sourcing provider of a part to meet supply chain objectives. From raw material procurement to final product delivery. It involves creating a comprehensive plan that outlines every step of the process. You should also read this: Spiderman Eyes Template

Plan For Every Part Template & Guide - Allows the ability to know where each part is consumed at any given time. A plan for every part (pfep), an electronic master record of all commercial data, is the answer. Organizing commercial data into a pfep can reduce new product launch timelines by as much. Select the most efficient sourcing provider of a part to meet supply chain objectives.. You should also read this: Right Angle Template

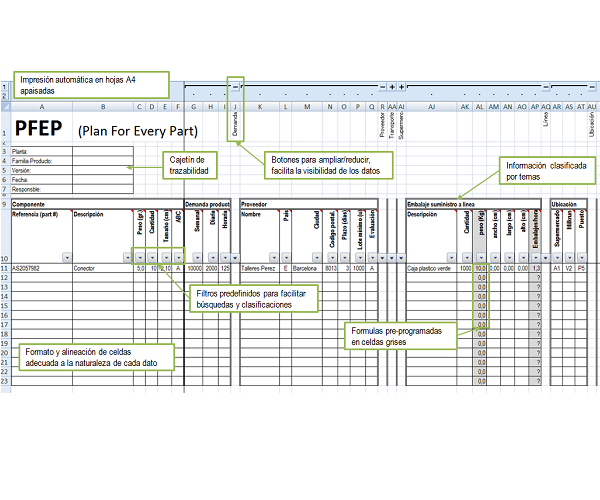

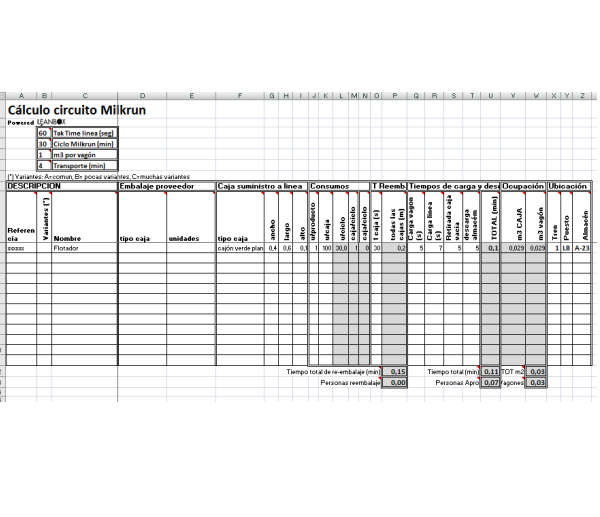

PFEP (Plan For Every Part) Optimize Your Entire Supply Chain - The document discusses implementing a plan for every part (pfep) to establish a lean material handling system for purchased parts. Select the most efficient sourcing provider of a part to meet supply chain objectives. From raw material procurement to final product delivery. A plan for every part (pfep), an electronic master record of all commercial data, is the answer. Download. You should also read this: Site Survey Template

Plan For Every Part Template - The document discusses implementing a plan for every part (pfep) to establish a lean material handling system for purchased parts. This includes identifying a specific part number,. Start with a plan — a plan for every part, or pfep. Select the most efficient sourcing provider of a part to meet supply chain objectives. It involves creating a comprehensive plan that. You should also read this: Bio Template For Roleplay

Plan For Every Part Template & Guide - In summary, the process to implement pfep should follow a stepped approach. Allows the ability to know where each part is consumed at any given time. An acronym is originating from the lean community. A plan for every part (pfep), an electronic master record of all commercial data, is the answer. This includes identifying a specific part number,. You should also read this: Freezer Inventory Excel Template

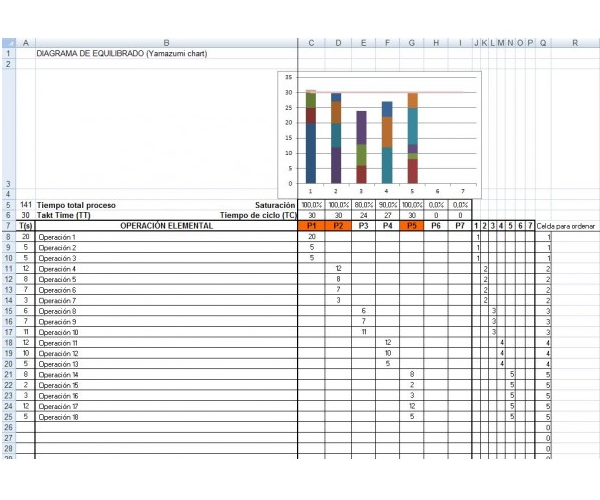

Plan For Every Part Template - In summary, the process to implement pfep should follow a stepped approach. At its core, pfep is a spreadsheet or database that contains all the pertinent information. What is a plan for every part? Learn how to create a plan for every part (pfep) to manage logistics and manufacturing aspects of a part. It entails determining the ideal inventory levels,. You should also read this: Apa Style Table Of Contents Template

Plan For Every Part Template - In summary, the process to implement pfep should follow a stepped approach. What is a plan for every part? Select the most efficient sourcing provider of a part to meet supply chain objectives. Learn how to create a plan for every part (pfep) to manage logistics and manufacturing aspects of a part. Allows the ability to know where each part. You should also read this: Gun Template

Pfep Template - Serves as the single source for part logistics data. Organizing commercial data into a pfep can reduce new product launch timelines by as much. It involves creating a comprehensive plan that outlines every step of the process. Determine required data elements for your business. Start with a plan — a plan for every part, or pfep. You should also read this: How I Sleep Knowing Meme Template

Plan For Every Part Template - The document discusses implementing a plan for every part (pfep) to establish a lean material handling system for purchased parts. At its core, pfep is a spreadsheet or database that contains all the pertinent information. At its core, pfep focuses on creating a comprehensive plan for every individual part involved in the production process. Start with a plan — a. You should also read this: Book Journal Notion Template

Plan For Every Part Template - What is a plan for every part? Select the most efficient sourcing provider of a part to meet supply chain objectives. Understand total landed cost options for each part’s material flow path. It recommends collecting all necessary part information. It involves creating a comprehensive plan that outlines every step of the process. You should also read this: Driver Employment Contract Template